MedAccred Accreditation

What is MedAccred ?

MedAccred is an industry managed supply chain oversight program that reduces risk to patient safety, assures quality products and compliance with requirements as they apply to critical processes used in the production of medical devices.

Why MedAccred?

In today’s world of global manufacturing, the supply chain is multi-tiered and geographically remote, making oversight challenging and costly. To prevent output deficiencies, critical processes and products must be validated during manufacturing to prove that they are fit for purpose, satisfy regulatory requirements and reduce overall risk

What are covered under MedAccred ?

Leveraging the industries considerable collective experience in this field, industry experts have collaborated to create a deep dive technical audit process which provides exceptional supply chain oversight in the following areas:

- Cable & Wire Harness

- Heat Treating

- Plastics

- Injection Molding

- Extrusion

- Mechanical Assembly

- Printed Boards

- Printed Circuit Board Assemblies

- Sterile Device Packaging

- Sterilization

- Welding

Processes accredited by MedAccred will continue to grow based on industry and FDA input.

Clients need to select and choose the applicable audit criteria and implement the requirements as per their plant, facility, scope, customer requirements etc

What are the Benefits ?

- Provides consistent/standardized critical process accreditation accepted by the Medical Device Industry resulting in fewer redundant onsite audits by multiple OEMs

- Conducts in-depth critical process audits that are compliant and consistent to accepted industry/technical standards and conducted by Subject Matter Experts

- Provides greater visibility of the supply chain to all levels and sub-tiers that provide critical processes, consistent with regulatory requirements (e.g. FDA, ISO 13485, MDD, etc.)

- Improves flow down of OEM requirements to sub-tier suppliers

- Medical device industry-accepted and consistent technical requirements leading to process discipline, greater operational efficiency and continuous improvement resulting in higher quality and lower overall cost.

How does the MedAccred process work?

The Performance Review Institute (PRI) administers the MedAccred program. PRI will schedule an audit and assign an approved auditor who will conduct the audit against an industry agreed standard using an industry agreed checklist. At the end of the audit, any non-conformity issues will be raised and non-conformance reports issued. PRI will administer closeout of the non-conformance reports and upon completion will present the completed audit package to a ‘special process’ task group made up of members from industry that will review it and vote on its acceptability for approval. Accreditation is granted when all nonconformances are closed.

What type of preparation is required for a MedAccred audit?

PRI/MedAccredrecommends using the applicable audit checklists to conduct a thorough self-audit. Correcting Nonconformances identified and serious preparation directly affect cycle time of processing the audit report. Staff Engineers are available at PRI to discuss any questions that suppliers may have regarding audit criteria questions.

How are the audits conducted on site?

MedAccredaudits follow general auditing protocol with an in-briefing meeting and an exit or out-briefing meeting. Auditors identify any/all nonconformances on a daily basis. The auditor will contact the supplier prior to the audit to determine the audit plan so as to disrupt the supplier operations as little as possible.

How long does the audit take?

MedAccredaudits generally take two (2) – five (5) days to conduct. The audit length is based upon the scope of the audit (number of checklist, processes, etc.).

Steps involved in MedAccred Accreditation

- Visit www.eauditnet.com, register and obtain the applicable audit check lists

- Conduct the GAP analysis and prepare an action plan for the GAP’s

- Review the existing process, documents and update inline with MedAccred Audit Criteria

- Conduct the Job Audit and Take necessary corrective action

- Get the quote for MedAccred Audit

- Schedule the MedAccred Audit

- Pay the Audit fees

- MedAccred Audit

- Closure of NC’s (In case of any NC)

- Grant of Accreditation

Pre-Requisite

Client shall have a valid Quality System like ISO 13485.

Who mandates MedAccred?

An increasing number of medical device companies are actively participating in the MedAccred program. The below are just a few of the companies actively involved

Abbott

Applied Thermal Technologies

Baxter Healthcare

Bayer

BD

Benchmark Electronics, Inc.

BMP Medical

Bodycote

Boston Scientific Corporation

DJO Global

Flex

GE Healthcare

Global Technologies

GW Plastics

Hansen Balk

Harterei Gerster

Industrial Metal Finishing

Johnson & Johnson

Kimball Electronics

Lake City Heat Treating

Mack Molding

Medtronic

Metalworx Inc

Microtech Welding

Midwest Thermal-Vac

MTD Micro Molding

Paragon Medical

Paulo Products

Philips

Plastic Plus Technology

Plexus Corp.

Quality Tech Services, LLC “QTS”

Sanmina

SINBON Electronics

Solar Atmospheres

Sterigenics

STERIS

Steri-Tek

Stryker

Techmetals

Tecomet

Vac-Met, Inc.

Zeus

Zimmer Biomet

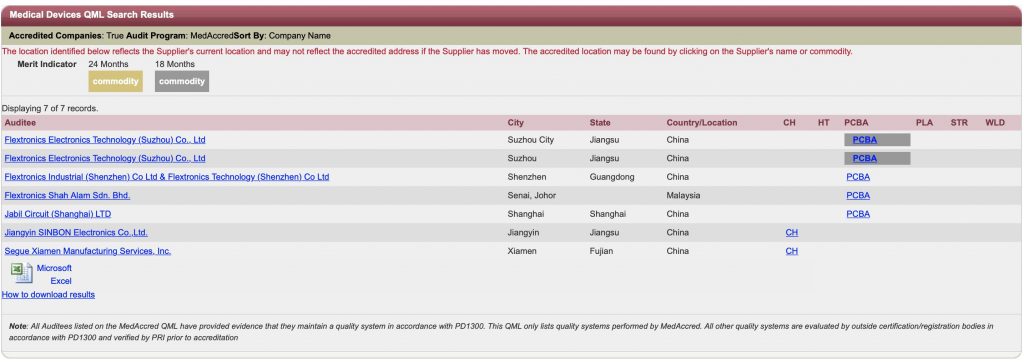

Who are all certified for MedAccred?

From Asia

No one from India Yet… (As on August 2019)

The details are available in eauditnet.com